|

|

"Twisting building" of super high rise buildings-Chongqing Hi-tech Sun Tower重庆高科太阳座位于重庆北部新区幸福广场,由Aedas负责建筑设计,以“极光”为概念,南北立面的弧形扭曲造型,成为标志性的特色和最大的技术难点。RFR担任双曲部分的幕墙顾问,双曲幕墙面积约8000平方米,双曲幕墙板块数量多达1709块。 Chongqing hi-tech sun tower is located in the happiness square in the northern New District of Chongqing. Aedas is responsible for the architectural design. With the concept of "Aurora", the arc-shaped and twisted shape of the north and south facades has become a landmark feature and the biggest technical difficulty. RFR serves as the curtain wall consultant of the hyperbolic part, with an area of about 8000 square meters and 1709 hyperbolic curtain wall plates. 重庆高科太阳座塔楼的最大单层扭拧角度达8.8度/层,约为目前全球单层扭拧角最大的F&F大厦的1.5倍,远超同类项目,有望在未来成为超高层建筑的“世界第一扭”。 The maximum torsion angle of the Sun Tower of Chongqing Hi Tech Co., Ltd. is 8.8 degrees per floor, which is about 1.5 times that of F & F building with the largest torsion angle in the world. It is far more than similar projects and is expected to become the "world's first twisting" of super high-rise buildings in the future. 高层建筑和城市住宅委员会(CTBUH)在2016年对于全世界扭转塔楼进行了研究,从高度、结构紧实度以及总扭转度数进行分析比较,得出巴拿马城的F&F大厦(233米)是当时世界上单层扭转角度最大的超高层建筑,最高达5.943度/层。 In 2016, the Committee on high rise buildings and urban housing (CTBUH) conducted a study on torsion towers all over the world. Through the analysis and comparison of height, structural compactness and total torsion, it is concluded that the F & F building (233m) in Panama City was the super high-rise building with the largest torsion angle of single story in the world at that time, with the highest torsion angle of 5.943 degrees / floor.

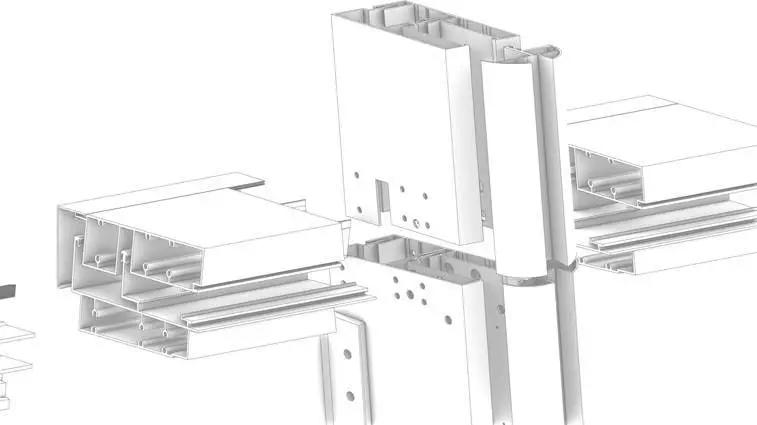

对于性能和加工精度都要求较高的超高层单元幕墙,拟合双曲面一直是一大难题。在本项目中,RFR的幕墙团队与Aedas的建筑师深度合作,应用了两大关键性技术——双曲单元玻璃冷弯,复杂曲面幕墙设计和BIM,挑战世界级难度,实现标志性的建筑形态。 For the super high-rise unit curtain wall which requires high performance and processing accuracy, fitting double curved surface is always a big problem. In this project, the curtain wall team of RFR cooperated deeply with the architects of aedas, and applied two key technologies -- double curvature unit glass cold bending, complex curved surface curtain wall design and BIM, which challenged the world-class difficulty and realized the landmark architectural form. 1. 双曲单元玻璃冷弯技术 COLD BEND GLASS TECHNOLOGY 利用冷弯拟合技术设计扭转曲面玻璃,每块玻璃的尺寸大小以及扭曲程度均不同,成功地用平板玻璃代替双曲玻璃,节省了1100万的建设成本。 Using the cold bending fitting technology to design the twist curved glass, the size and twist degree of each glass are different. The flat glass is successfully used to replace the hyperbolic glass, saving 11 million construction cost.

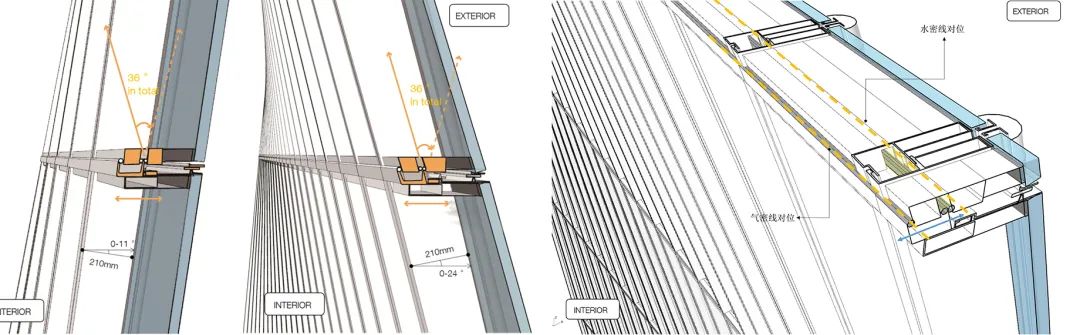

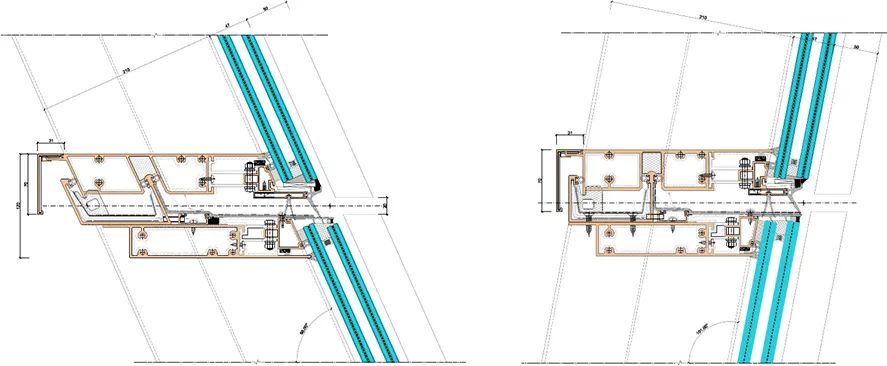

玻璃分格的每三个顶点形成的平面与第四点的距离最小的,即为此块玻璃分格的最适平面。这个距离即为将平板玻璃冷弯成双曲玻璃的冷弯量。本项目冷弯量最大为86mm,之后通过计算验证此冷弯量在许可范围之内,可以满足设计要求。 The plane formed by every three vertices of the glass partition has the smallest distance from the fourth point, which is the most suitable plane for the glass partition. This distance is the amount of cold bending from flat glass to hyperbolic glass. The maximum cold bending capacity of this project is 86mm, which can meet the design requirements. 02. 复杂曲面幕墙设计和BIM技术 COMPLEX GEOMETRY FACADE DESIGN & BIM 独创的幕墙系统使之能适应单元板块多角度,多尺寸变化的要求,并保证幕墙性能。 The original curtain wall system can adapt to the requirements of multi angle and multi size change of unit plate, and ensure the performance of curtain wall. 由于立柱的倾斜角的变化,导致立柱和横梁相对对位的角度和位置关系变化。这个数值决定了系统横框的种类。上横梁的上部分采用分体设计,每2.5度开一套模具,并根据倾角前后错动,与立柱内腔壁(气密线、水密线)对位。 Because of the change of the tilt angle of the column, the relative alignment angle and position relationship between the column and the beam change. This value determines the type of system transom. The upper part of the upper crossbeam adopts split design. A set of mould is opened every 2.5 degrees, and moves forward and backward according to the inclination angle to align with the inner cavity wall (air tight line and water tight line) of the column. 在本项目中,真正做到了从整体几何优化分析,幕墙模型建模,LOD400加工图深度构建建模,到加工图数据自动生成和检查的全过程幕墙BIM流程,保证效果要求和设计思路的完整贯彻。BIM系统在方案初期模拟真实构件的效果,达到对设计呈现的效果最大把控。 In this project, the whole BIM process of curtain wall is achieved from the overall geometric optimization analysis, curtain wall model modeling, lod400 processing drawing depth construction modeling, to the automatic generation and inspection of processing drawing data, so as to ensure the complete implementation of effect requirements and design ideas. BIM system simulates the effect of real components in the early stage of the scheme to achieve the maximum control of the design effect.

03. 可行性验证 FEASIBILITY VERIFICATION 通过“双曲单元玻璃冷弯”,“复杂曲面幕墙设计和BIM”两个关键性技术,团队解决了平板玻璃拟合双曲面的难题,实现了建筑立面柔美的弧线效果。在招标阶段之前,我们进行了玻璃冷弯试验,证实了设计假设的可行性。 Through two key technologies of "double curved unit glass cold bending" and "complex curved curtain wall design and BIM", the team solved the problem of flat glass fitting double curved surface, and realized the soft arc effect of building facade. Before the bidding stage, we carried out the glass cold bending test, which confirmed the feasibility of the design assumption. 根据有限元分析结果,基于整块建筑幕墙上冷弯后应力最大的玻璃,冷弯试验选取3片玻璃样品,进行冷弯前表面应力测量,分级施加冷弯量,并记录变化。试验结果证明玻璃样品能够承受最大设计值的冷弯量86mm。创新的设计与细致的求证工作为项目的实现打下了坚实可信的基础,规避了合约及安全风险。 According to the results of finite element analysis, based on the glass with the largest stress after cold bending on the whole building curtain wall, three pieces of glass samples were selected for cold bending test to measure the surface stress before cold bending, apply the cold bending amount step by step, and record the change. The test results show that the glass sample can withstand the maximum design value of 86 mm cold bending. The innovative design and meticulous verification work have laid a solid and reliable foundation for the implementation of the project, avoiding the contract and security risks. 目前,重庆高科太阳座项目已进入塔楼外装塔冠钢结构安装、消防安装和空调管道施工阶段,计划于今年年底竣工。与其它扭转形体幕墙相比,重庆高科太阳座项目利用较少种类的型材模具和冷弯拟合,保证曲面平顺无错台凹凸的效果。我们期待它以标志性的建筑轮廓,为重庆市民的公共空间增添特色,成为极具活力和辨识度的城市新地标。 At present, Chongqing hi tech tower project has entered the stage of steel structure installation of tower crown, fire protection installation and air conditioning pipeline construction, and is planned to be completed by the end of this year. Compared with other twisted form curtain walls, Chongqing hi tech sun block project uses less kinds of profile molds and cold bending fitting to ensure smooth surface without staggering and concave convex effect. We expect it to add features to the public space of Chongqing citizens with its landmark architectural outline, and become a new urban landmark with great vitality and recognition.

|